-

REPAIR

FUEL TANKS

Based on the qualifications held, No. UC-09-90-N / 3-12 We provide comprehensive repair and renovation services for tanks. -

REPAIR

FUEL TANKS

Based on the qualifications held, No. UC-09-90-N / 3-12 We provide comprehensive repair and renovation services for tanks. -

REPAIR

FUEL TANKS

Based on the qualifications held, No. UC-09-90-N / 3-12 We provide comprehensive repair and renovation services for tanks. -

REPAIR

FUEL TANKS

Based on the qualifications held, No. UC-09-90-N / 3-12 We provide comprehensive repair and renovation services for tanks. -

REPAIR

FUEL TANKS

Based on the qualifications held, No. UC-09-90-N / 3-12 We provide comprehensive repair and renovation services for tanks. -

REPAIR

FUEL TANKS

Based on the qualifications held, No. UC-09-90-N / 3-12 We provide comprehensive repair and renovation services for tanks.

Offer

Double-jacket - the second bottom in ground and underground vertical tanks

Creating a second floor in vertical above-ground storage tanks is analogous to our ZET Alupłaszcz system in underground tanks.

The jacket is made in combination of an aluminum-resin composite, with an electro-conductive coating applied to the bottom and side walls of the tank up to 1 meter.

The interstate space prepared in this way protects against the release of petroleum products into the ground, thanks to equipping the tank with an electronic monitoring system that distinguishes the type of leakage (water / product).

In order to increase work safety, we also perform painting with electrostatic discharge paint on the entire interior surface of the modernized tank.

A double-walled tank in underground tanks with a horizontal axis

The second wall with the creation of interstitial space - fuel stations

The Zet Alupłaszcz system is an award-winning and patented service created as an alternative to the installation of new fuel tanks. It consists in making a second coat in steel, single-wall tanks intended for storage of liquid products. The jacket is made in combination of an aluminum-resin composite with an electrically conductive coating. The tanks are equipped with an electronic monitoring system that distinguishes between types of leaks (water / product).

Product innovation:

The Zet Alupłaszcz system is an award-winning and patented service created as an alternative to the installation of new fuel tanks. It consists in making a second coat in steel, single-wall tanks intended for storage of liquid products. The jacket is made in combination of an aluminum-resin composite with an electrically conductive coating. The tanks are equipped with an electronic monitoring system that distinguishes between types of leaks (water / product).

Product innovation:

- The use of aluminum sheets as the second coat in tanks, which significantly extend the life of the tank.

- Optional production of a metallic (aluminum) surface inside the tank. The internal aluminum coating is a great electric conductor and thus the ideal discharge of the electrostatic charges of the tank. It significantly improves the safety of the fuel tank

- Before applying the second coat, the external steel tank is reinforced on the entire inner surface by lining it with a glass mat reinforced laminate. It extends the life of the external tank to a considerable extent.

- The technology used allows the application of a second coat in tanks covered with a laminate coating, without the need to remove the coating -

- An easy method for the possible repair of the tank even when the outer jacket is unsealed, without having to break the entire inner jacket.

- The use of liquid sensors monitoring the interstitial space cooperating with various centrals of the market leading providers of measurement systems for the status of stored products. This solution does not require a separate central unit for leakage sensors.

Repairs and modernization of above-ground and underground storage tanks

Based on the rights held, No. UC-09-90-N / 3-12, we perform comprehensive repair and renovation services for tanks.

These include, among others, works related to: removal of tank leaks by welding, making reinforcing parts (such as sun, struts and rings). We also equip tanks with the necessary installations, among others, anti-knock valves and breathing valves.

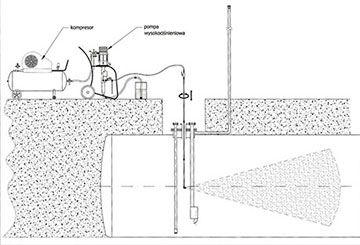

Safe tank cleaning

The tank, after pumping out fuel from it due to the vapors floating in it, is a very explosive environment, and thus poses a great threat to the work of people in this zone.

To avoid the risk of explosion, our second-degree research and measurement laboratory has developed a proprietary safe method for degassing and cleaning the fuel tank. This method significantly limits the presence of people in the danger zone when preparing the fuel tank for further work, significantly increasing their safety during works.

Our service has received a positive opinion from health and safety experts and fire service, confirming that we work in accordance with applicable health and safety, environmental protection and environmental protection regulations for gas stations and fuel depots.

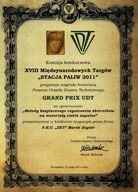

An additional advantage proving the innovation of our service is the fact that it was awarded by the Office of Technical Inspection and the Polish Chamber of Liquid Fuels at the 18th International Trade Fair "Fuel Station" in 2011.

The innovative method of cleaning and degassing the fuel tank is a pioneer service of this class on the Polish market, filed in the Patent Office under number 391542. During the conduct of all activities, the rules to counteract the threat are preserved.

Among others:

To avoid the risk of explosion, our second-degree research and measurement laboratory has developed a proprietary safe method for degassing and cleaning the fuel tank. This method significantly limits the presence of people in the danger zone when preparing the fuel tank for further work, significantly increasing their safety during works.

Our service has received a positive opinion from health and safety experts and fire service, confirming that we work in accordance with applicable health and safety, environmental protection and environmental protection regulations for gas stations and fuel depots.

An additional advantage proving the innovation of our service is the fact that it was awarded by the Office of Technical Inspection and the Polish Chamber of Liquid Fuels at the 18th International Trade Fair "Fuel Station" in 2011.

The innovative method of cleaning and degassing the fuel tank is a pioneer service of this class on the Polish market, filed in the Patent Office under number 391542. During the conduct of all activities, the rules to counteract the threat are preserved.

Among others:

- Securing employees at every stage of cleaning

- Constant measurement of vapor concentrations by means of an explosometer

- Using tools and devices that are safe.

Liquidation of tanks and petrol stations

Our company also deals with the inactivation of tanks and petrol stations. Works are carried out in two ways, by flooding the reservoir with water or water with sand, and complete excavation of the reservoir along with possible land reclamation.

The scope of the service also includes all additional work related to the liquidation of tanks, such as cleaning and degassing the tank, as well as disassembly of distributors and technological installations.

Repairing the sideburns

In addition to the modernization of fuel tanks at service stations, the company deals with the repair of leaks in steel and aluminum fuel tanks:

car

agricultural machines (in tractors, combines, tractors, mowers, etc.)

construction equipment (in excavators, bulldozers, rollers, etc.)

other internal combustion vehicles

Types of repairs:

surface cleaning (sanding)

removing leaks (welding)

surface renovation (laminating)

comprehensive repair (welding and laminating)

Means of delivery and collection of the fuel tank (optional):

- the removed fuel tank the customer delivers to the contractor and receives after the service

- the fuel tank is disassembled at the contractor's office, after the service the contractor assembles the tank in the vehicle

Warranties:

for welding - 12 months

for laminate protection - 5 years

Contact person:

Marek Zapiór, mobile: 609 427 222

e-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Zapraszamy Państwa do współpracy.

20 years of experience

The company is people

We cooperate both with individual clients and large oil companies, and take advantage of state-of-the-art solutions, materials, and equipment provided by renowned manufacturers.

P.H.U. ZET Marek Zapiór has won many prestigious awards, including the Prize of the President of the Office of Technical Inspection 2008 and 2011, the prizes of the President of the Polish Chamber of Liquid Fuels 2011 and the title of the National Leader of Innovation.

Innovations

Inspection robot

Remote internal revision with the help of a robot is an innovative service involving the visual assessment of the condition of the internal surface of steel walls of tanks intended for storing inflammable liquid materials

Safe tank cleaning

The tank after pumping out the fuel from it due to the vapors floating in it is an explosive environment. In order to counteract the work of people in explosion danger zones, as it has been so far, our 2nd-level Test and Measurement Laboratory has developed a proprietary safe method of degassing and cleaning.

Copyright ZET Zapiór 2024

Copyright ZET Zapiór 2024